Roller bearing is cylindrical, conical or drum-shaped roller for rolling element bearing. Roller bearings are mainly radial cylindrical roller, double row spherical roller, tapered roller and thrust roller and structure type.

2013年12月30日星期一

Bearings sales center edit

Bearings sales center edit , fall season, City ushered in the annual autumn festival investment and trade as one bearings for printing machine of the investment section of activities , Municipal Government on September 20 afternoon foreign investment in Hotel honor winner of the award ceremony. again won the " Best Foreign -invested enterprises in " title .

In this review , the again was named " Best Foreign -invested enterprises in City " title , China chief representative of the temple mound receive the award. Ltd. for its remarkable ability to promote economic development , and products with high technological content and many china bearings other advantages , has been highly praised by the municipal government , has been selected as the 2009 Best Foreign -invested enterprises in City , China's total as a representative of the temple mound , general manager of the enterprise received a municipal award .

in Japan since 1916, first began production of bearings , bearing a Japanese pioneer in the development and provision of various types of bearings for the development and progress of machinery industry has made a great contribution. Now , bearing areas , ranking first in Japan , but also in the forefront in the world . through a global network of mutually reinforcing efforts to promote development capabilities , production capacity, sales ability and business management capabilities , and strive for greater progress.distributor in China , according to reports, this is the Kunshan NSK company following the 2006 , 2007 , 08 years later, this is the fourth consecutive year "Best Foreign Investment Enterprise" award this honor .

2013年12月26日星期四

often accompanied by fatigue cracks

Contact fatigue spalling occurs in INA bearing surface , often accompanied by fatigue cracks , first produced from the contact surface of the following maximum alternating shear stress , and then extended to the formation of different surface flaking shapes, such as point-like pitting or pitting as spalling , flaking into small pieces called superficial peeling. Due to the gradual expansion of flaking surfaces , but often extend to the deep , forming deep peeling. Deep contact fatigue double row cylindrical roller bearing spalling is a source of fatigue failure .

Continuous wear will cause spherical roller thrust bearing parts gradually damage and eventually lead to the loss of dimensional accuracy INA bearings and other related issues . Wear may affect the shape change , with the gap increasing and work surface morphology changes that may affect the lubricant or it reaches a certain level of pollution caused complete loss of lubrication , which makes bearings and even the loss of rotational accuracy can not operate normally . Wear failure is one of the kinds of bearings common failure mode, press the wear is usually divided into the most common form of abrasive wear and adhesive wear .

2013年12月21日星期六

Sweden Bearing Group agreed to acquire the company Japan cage factory in Gothenburg because

Sweden Bearing Group agreed to acquire the company Japan cage factory in Gothenburg because: will gradually thrust ball bearing sell parts do not belong to the core business of the manufacturer, which is part of the long-term development strategy. is our approved suppliers, they will continue after the acquisition, investment operations cage factory in Gothenburg. At the same time, but also for SKF in Gothenburg and elsewhere to provide products. SKF NKC has been named the 2007 Supplier of the Year.

Sweden Bearing Group cage in Gothenburg factory is located in the production area, has 130 employees. To in Gothenburg, Hanover Luton , Nilai (Malaysia) and (Germany) production plant to provide products. Japan Company acquired in Gothenburg cage factory, cage factory in Gothenburg will be serving customers in Europe manufacturing china bearings and sales base. The company plans to maintain the existing plant and production scale, continue to F in Gothenburg and elsewhere to provide products.

????? According to East distributor introduced, was founded in 1924, is a cage manufacturing, stamping steel parts as well as plastic and rubber processing a global leader. Group has signed Company acquired SKF cage factory in Gothenburg protocol, the acquisition is expected to be completed the second quarter of this year.

2013年12月17日星期二

To bring best practices knowledge

To bring best practices knowledge

Experiences using other plants

Development of cost-effective PdM activities

Integrated hardware, software and data configuration

Small impact on staff

Rapid results

Use of existing tools and techniques

Sweden Bearing Applications integrated device reliability program case:

In the 15 plants have 27 coal and gas supply companies operating unit is facing reliability and tapered rollers performance issues. The goal is to reduce equipment failure, appropriate centralized maintenance resources. SKF has developed a proactive maintenance program, focusing on critical equipment planned maintenance and major failure china bearings mechanism. As more attention to the task of those states to monitor and eliminate unnecessary tasks, the plant reduced maintenance costs, SKF Bearing solutions and improve the availability and reliability

2013年12月9日星期一

Environmental protection is one of today's society a constant topic today

Environmental protection is one of today's society a constant topic today, SKF bearings distributor in China and introduce you to the future SKF technology environmental protection. SKF in the maintenance and operational experience in the field helps to make existing operations more streamlined and efficient, and applied to the new design special bearing and the concept of alternative energy sources such as the SKF expertise and technology is more regarded as extraordinary.

in the wind and other renewable energy sources has extensive experience in the field. For example, an innovative series of SKF Nautilus bearing solutions enable wind turbine manufacturers to abandon the spindle, thereby reducing the weight of the generator, reducing size and friction, ultimately increase this clean, renewable energy production.bearings,tapered rollers seals and lubrication systems also help extend the life of solar energy equipment, particularly in harsh environments and extreme temperatures. actuators and control unit helps to make the building self-regulating system blinds warmer in winter, cooler in summer. Such a system equipped with SKF products can reduce HVAC (HVAC) Energy consumption: 30-35% decrease in winter, summer reduced by half.

2013年12月5日星期四

Bearing on the state of damage

Machine shaft parts, especially the spindle , usually with rolling bearings or sliding bearings assembled into one , and a high speed of rotation , and sometimes it will produce a very high heat. This phenomenon if not removed , will cause angular contact ball bearings overheating , and to the corresponding parts of the machine to produce thermal deformation temperature , causes severe spindle and tailstock is not high , which not only affects the accuracy and precision machine itself and bearing will burn .

In general, if used correctly KOYO bearings can be used to reach far fatigue life. Accidental injury prematurely but there can not be resistant in case of use This early damage and fatigue life relative , a failure or an accident is called the quality of use limits. Multiple causes the installation , pay attention to the lubrication on the use , invading foreign body from the outside , for the study of the shaft , the thermal paired tapered bearing effects of inadequate housing and so on.

Bearing on the state of damage , such as: angular contact ball bearing rings , ribs cards injury, may be considered as a reason for lack of lubricant , not suitable for the oil discharge structure defects, the intrusion of foreign bodies , bearing misalignment , shaft deflection is too large , there will be overlap of these reasons .

Thus , the survey only bearing damage , it is difficult to know the real cause of injury. However , if you know the use of machinery, conditions of use, the bearing structure around the bearing exporter bearing , to understand the situation before and after the accident , combined with state of the bearing damage , and several reasons, we can prevent similar incidents from recurring.

Bearings are available to determine , mainly on account of the extent of damage KOYO bearings , mechanical properties, the importance of operating conditions to be determined during the next overhaul . If you have the following defects can no longer use , must be replaced with new angular contact ball bearings. Inner ring, outer ring, rolling elements of any cracks or gaps on the holder .

1 , rings , there is a fracture of any body roll .

2, there is a significant injury on the rolling pavement card , ribs , rolling .

3 , cage or wear significantly rivet significant relaxation .

4 , raceway , there is rust on the rolling body injury .

5 , raceway , and playing serious indentation marks on rolling .

6 , the inner diameter surface or outer diameter surface creep significantly .

7 , discoloration caused by heat significantly .

8 , grease sealed bearings , seals or dust cover damaged significantly .

2013年12月2日星期一

Thrust ball bearing is a separate type of bearings

Thrust bearings are used exclusively dedicated bearing axial force is the force in the direction parallel to the axis of the bearing . Thrust bearings are also known as thrust bearings.

The thrust bearing is generally composed of two or more thrust washers thrust washers and several rolling slim section ball bearing body composition, general thrust washer into the shaft piece and seat piece , rolling is generally the most common type of iron or copper combined into the overall quality of the cage which is the most common type of ball bearing type thrust bearings.

Thrust ball bearing is a separate type of bearings , shaft ring , seat ring and the cage , ball component separation . Shaft ring is cooperating with the shaft collar , seat is compatible with the bearing hole ferrule , and there is a gap between the shaft ; thrust ball bearings can only bear axial load , one-way thrust ball bearings can only bear axial loads in one direction , two-way thrust ball bearings can withstand axial load in both directions ; thrust ball bearings can not restrict the shaft radial paired tapered bearing displacement , low speed limits , one-way thrust ball bearings can limit a shaft and housing the axial direction of displacement , two-way bearing to limit the axial displacement in both directions .Thrust roller bearings for axial load mainly axial , radial joint load , but the radial load should not exceed 55% of the axial load . Other thrust roller bearings, such bearings lower friction coefficient , high speed, and aligning performance . 29000 bearing stick asymmetric spherical roller , the roller can reduce the relative sliding and rolling in the work , and the roller length , large diameter roller quantity, high load capacity, usually oil lubrication , individual low speeds available greased . In the design selection , preference should be given ; 80000 Thrust cylindrical roller bearings , 90000 Thrust tapered roller bearings and needle roller thrust bearings AXK type , can withstand a one-way axial load , than the axial thrust ball bearings much greater load capacity and rigidity, axial occupy a small space. Thrust cylindrical roller bearings and thrust needle roller bearings for low speed applications , thrust tapered roller bearing speed slightly higher than the thrust cylindrical roller bearings.

2013年11月24日星期日

paired tapered bearing rebar awarded the successful development and production .

Tonghua Iron and Steel Group has successfully developed high-speed wire rod production HRB400E

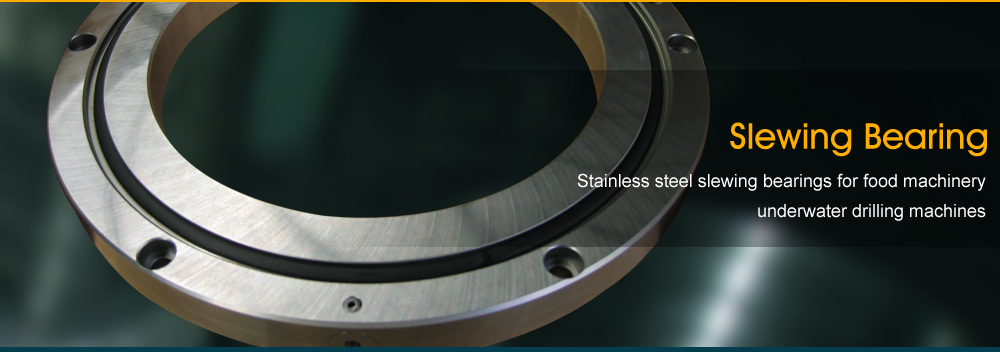

November 21 , Shougang Tonghua Slewing bearing Iron and Steel Group through high-speed wire rod plant new lines of production HRB400E8 mm rebar 42 99.7 tons , HRB400E8 mm rebar awarded the successful development and production .

It is understood , HRB400E test seismic reinforcement steel is rolling temperature requirements are very strict, new product development is currently under trial production stage. The production is the fourth rolling plant this year, but also the largest number of rolling , the best one, spinning temperature first drops 900 ℃, changing the spinning temperature is not lower than the previous record of 1000 ℃ for .

In the organization of production Stainless steel slewing bearing process, production department and rolling mill plant personnel to develop a reasonable plan rolled repeatedly revised operating points , the technical personnel at the scene to track the guidance requires workers reasonable control roller speed to ensure open rolling temperature , temperature and spinning into the finishing temperature , strengthen

paired tapered bearinginspection of rolling groove , guide and guard the entrance , timely adjust the size of the finished wire , seismic steel products to ensure customer requirements for dimensional accuracy , quality assurance pruning to ensure end to end water cooling and defective parts are not all clean and trim so storage product quality to meet market and customer needs .

It is reported that the feedback data center sampling technique from watching the indicators uniformity , yield strength and tensile strength are up to quality requirements.

2013年11月17日星期日

may cause the rolling element and the raceway between the sliding destructive

In order to ensure Slewing bearing satisfactory performance , needle roller / angular contact ball bearings like all ball bearings and roller bearings , must always bear acting on the radial and axial certain minimum load , especially if they want to run at high speed or subjected to high accelerations or rapid changes in the load direction . Under these conditions , the rolling element and the inertia force of the retainer and lubricants friction bearing arrangement may play a deleterious effect on the rolling conditions , and may cause the rolling element and the raceway between the sliding destructive .

Increase in radial needle bearing backing bearings on the necessary minimum radial load can be estimated using the following formula :

Frm = 0.02 C

Angular contact ball bearings necessary minimum axial load can be calculated using the following formula :

Where

Cold start or lubricant viscosity is very high, even demanding loads. Bearing weight of the components together with external forces generally exceed the minimum necessary load. If this is not the case, you must give Needle roller / angular contact ball bearings impose additional radial and / or axial loads.

2013年11月10日星期日

NSK exclusive agent -Azam companies in Bangladesh

NSK exclusive agent -Azam companies in Bangladesh

NSK bearings distributor Slewing bearing in China editor , recently , from the Seiko Corporation of Japan (NSK LTD.) Was the headquarters of the conference call , NSK Bangladesh Azam Enterpris was nearly 2 billion company signed a cooperation agreement Kata and authorized Azam Company exclusive agent for the NSK Bangladesh in Dhaka, Bangladesh held a signing ceremony.

Attending the signing of the agreement by the authorized agents NSK Southeast Asia sales manager Dennis Sim, NSK Asia Pacific Application Manager Tanaka Hiroomi, Azam Enterprise Stainless steel slewing bearing general manager of Dhaka and marketing department managers Emamul Ahsan and so on.

Azam company became the sole agent in Bangladesh ceremony Azam Enterprise general manager Dhaka , said : "NSK two major areas of industrial and agricultural monthly demand of around 2 billion worth Kata bearings , Azam became the exclusive distributor of NSK Bangladesh help to improve buyer confidence in us , Azam Enterprise company mainly engaged in well-known national brands of bearings, has 35 years of history, has become the exclusive distributor in Bangladesh NSK , NSK Bearings responsible for regional sales in Bangladesh , and Azam within a year the company plans to set up sales elsewhere center

2013年11月4日星期一

which makes the cost reduction, the company brings considerable benefits

Swedish SKF Group Headquarters capacity to adjust

SKF bearings distributor in China sales center edit, Sweden, SKF Group's official website revealed that in March 2010, the Swedish SKF Group successfully implemented adjustment which is located in Gothenburg, Sweden, headquarters of the production Roller bearing capacity, the program is expected to involve about 150 people, realignment of headquarters capacity costs about 90 million kronor.

It is reported that last year, the Swedish SKF Bearing Group headquarters to face the financial crisis and lower market demand for capacity to try to carry out adjustments based solution, which makes the cost reduction, the company brings considerable Precision bearing benefits. Implemented in March this year to adjust capacity based program package costs about 90 million Swedish kronor, will be credited to the income statement for the first quarter. These initiatives will be held no later than the third quarter of 2010, fully implemented, is expected to be generated when the gains of SEK 50 million.

Swedish SKF Group realignment of headquarters staff capacity in order to avoid redundancy, while weak demand for consultation by the union representatives of the solutions successfully implemented last year to prove that the solution can be kept core skills and avoid production interruptions.

2013年10月24日星期四

inner and outer rings, rolling a strip of any one there.

c. raceway, ribs, rolling a significant injury card.

d. confrontation frame badly worn or loose rivets ferocious.

e. raceway, rolling rust and have scars.

f. rolling surface, rolling on and playing a significant indentation marks.

g. inner diameter surface or outer diameter on the creep.

h. overheating discoloration ferocious.

i. grease seals and dust sealed bearings to severe damage.

Nsk Backing bearings in use, sometimes we can hear bearing noise, in fact, theoretically, the bearing itself does not produce noise, and the noise we heard was bearing directly or indirectly arising from the surrounding structure vibrating sound effect. So, why would the bearing vibration it? Today, it is for me to explain something simple for everyone, please read carefully!

When changes in the number of rolling loads, will produce excitation when a radial load on a load of imported backing bearings its load bearing rolling element number will be some changes in the operation, which caused the load shift direction . The resulting vibration is inevitable, however, now seems to have a bearing vibration and noise are reduced, which is why? Nsk bearings due to the current use of the design to reduce the pre-load, rolling load at all, thereby reducing vibration, but also reduces the noise. Although the use of the pre-loaded, but can not completely relieve the vibration and noise problems. So, how to further reduce the noise it?

1, to prevent resonance excitation components and between the components of the vibration excitation.

2, change the stiffness, and to achieve the purpose of changing the critical frequency.

3, remove the critical excitation vibration.

2013年10月9日星期三

Hunan Timken Company general manager

Hunan Xiangtan city leaders to guide the work of Timken Company

TIMKEN TIMKEN tapered bearing Company China Limited Hunan Xiangtan municipal leaders 2010.04.30 Tao , deputy inspector of new water Deputy Minister , Office Yuan Xihui City Code , City Code Office deputy researcher Wu Ming and other city leaders to Hunan Xiangtan Timken company guidance .

Hunan Timken Company general manager , Mr. James Ai Gete water to guide the work of the new pottery reported Hunan TIMKEN COMPANY , and government leaders attach importance to and guide the company deeply grateful. Xiangtan City , Hunan Leading Tao fresh water to guide the work of Timken Company , said: "The government will be great support from the policy , the working group at any time improve coordination of services , the company provides a good investment environment . Provide good service for the enterprise , and effectively solve problems for them . "

About Timken Company in Hunan : Hunan Timken backing bearings Company is the world's largest earlier this year by the United States, one bearing manufacturer Timken Company and Xiangtan Electric Manufacturing Co., Ltd. joint venture , mainly the production of large wind turbine drive spindle Timken bearings , located in Xiangtan high-tech Zone industrial Park in Germany , is the Timken in China 's first six plants. (Timken bearings distributor in China Editor )

2013年10月8日星期二

nteract with senior engineers to understand the global leader in bearing technology

Shanghai Jiaotong University Li-Feng Xi dean renew Timken Scholarship , said: " Thank you very much Timken Company continues to provide scholarships to support my school education development and personnel training , while also hoping Timken Company in the field of mechanical engineering experience and technical advantages , together for the training of the younger generation of innovative engineering talents and efforts . "

Back in 2006 , Timken Company and the Shanghai Jiaotong University jointly established the " Shanghai Jiaotong University Timken Scholarship" , winning students not only get grant funds , as well as the opportunity to visit Timken Timken bearings located in Wuxi engineering training center, interact with senior engineers to understand the global leader in Tapered bearing technology . Timken also established with China Timken other prestigious scholarships to train in different fields of engineering and technical personnel.

TIMKEN Timken join Shanghai Jiaotong University scholarship renewed in order to continue to accelerate the pace of development in China , helping China 's top backing bearings schools to train more outstanding graduates to build a solid professional knowledge , with a first-class team of engineers innovative thinking . Ethics and Integrity is Timken 110 years of development history in one of the core values advocated , but also the spirit of relentless innovation Timken Bearing Company is proud heritage.

2013年9月29日星期日

I wish you all a Happy New Year floating Enns

In the past year, Enns floating in the new and old customers trust and support, and achieved excellent results. In order to thank new and old customers long-term sales of imported bearings on Enns floating center support in the 2010 New Year's Day approaching, Enns floating Backing bearings sales center, general manager with the staff wish you all a Happy New Year and good luck, plenty of money, career more on a new level.

Enns Floating Bearing Sales Center brands imported bearings, including Sweden SKF Bearing, Japan NSK Bearings, Germany FAG bearings, Japan NTN Bearing, the United States TIMKEN bearings, Germany INA Bearing, IKO needle roller bearings imported bearings brands. Products involved: deep groove ball bearings, cylindrical roller bearings, tapered roller bearings, aligning ball bearings, spherical roller bearings, needle roller bearings, angular contact ball bearings, thrust ball Slewing bearing thrust roller bearings, spherical plain bearings, spherical bearings, and linear guide series.

2010 New Year's Day is a new starting point, represents a promising year, we imported bearings sales center Enns float will make more effort to the best quality, best price, fastest speed, the best service to repay the new and old customers.

2013年9月28日星期六

Timken participate in the 2010 International Wind Energy Conference and Exhibition

In the May 22 to 26 , Timken took hold at the 2010 Dallas International Wind Energy Conference and Exhibition , Timken to the global wind industry shows an unprecedented number of new product developments . We follow Timken Timken bearings distributor in China to learn to participate in the 2010 International Wind Energy Conference and Exhibition highlights the main technical innovation of new products .

Timken in 2010 International Wind Energy Conference and Exhibition unveiled products include:

( 1 ) New UltraWind Timken tapered roller bearings , with Germanischer Lloyd (Germanischer Lloyd) certified the industry's highest rated life . This large aperture spindle Slewing bearing simplified drivetrain design , saving equipment costs ;

( 2 ) The new Timken? Antifriction bearings, including cylindrical roller bearings and spherical roller bearings : Compared to standard cylindrical roller bearings or spherical roller tapered bearing bearing this breakthrough technology will extend bearing life expectancy threefold. This new antifriction bearings can be reduced by up to 15 percent of torque, and can withstand abrasions , scratches , vibration and micro pitting corrosion and other damage ;

( 3 ) three new wind seal products, including : EcoTurn labyrinth , its non -contact design prevents grease leaks and contamination , ideal for Timken's low-pressure lubrication system ; Elastomer wind seal , in the design of the elastic sealing lip , can cope with the bearing deflection , and makes friction and minimize wear of the bearing inner ring ; , and wind seal PTFE , with excellent chemical inertness and low friction characteristics , helps to maximize product performance ;

( 4 ) of new wind energy equipment lubrication systems, precisely and evenly inject fresh grease lubricated bearings at the same time slot , can remove the old grease, significantly enhanced mechanical and electrical equipment performance and wind can produce . Its use is equipped with progressive or injector -based transmission -type centralized grease lubrication device ;

( 5 ) New frequency induction heaters , new frequency induction heaters , Timken? Clean steel , online intelligent monitoring systems , and Timken bearings company-specific Syber advanced wind energy systems analysis software performance products .

Timken participate in the 2010 International Wind Energy Conference and Exhibition to show more Timken is available from the wind industry to clean steel integrated powertrain solutions and services integration company , Timken has superior ability of being developed under megawatt generation customers excellent value and product lifecycle support. Meanwhile, The Timken Company and the world 's leading wind turbine manufacturers in a number of R & D level, extensive cooperation , and by virtue of its products are widely distributed in the global manufacturing and service network established a specialized service in the wind energy industry supply chain system.

2013年9月27日星期五

Dongfeng Honda Engine

Guangzhou NSK Bearings: NSK Honda presented to the "2010 Outstanding Supplier Award"

December 28, NSK backing bearings sales center in Guangzhou News - Guangzhou Honda Automobile, Dongfeng Honda Engine, Honda Motor (China) 3 companies in Guangzhou Baiyun International Convention and Exhibition Center jointly organized a grand 2011 Procurement Conference, to 2010 Excellent supplier awards, a total of 15 suppliers to get this award, NSK China is Honda "2010 excellent Supplier" award winner, one of the following NSK Slewing bearing sales center in Guangzhou reported.

NSK bearings distributor in China, according to reports, NSK (NSK China) Sales Co., Ltd. for the first time won the Honda three company's annual Supplier Excellence Award. Because NSK Southern Automotive Division and related auto parts production plants in terms of quality, price, delivery and other aspects of the previous year has been greatly improved, the maximum extent possible to meet the customer's production growth in demand, and thus subject to the customer's positive assessment.

We know that Guangzhou Honda, Dongfeng Honda, Honda (China) 3 Corporation is China's major automobile manufacturers, the main production Accord, Odyssey, Feng Fan, Fit, Costa figure, jazz and other models, and their suppliers standard is quite stringent. Guangzhou Honda, Dongfeng Honda Honda (China) 3 companies for outstanding supplier evaluation criteria QCDDM scoring criteria. Ie Q (quality)-C (Price)-D (delivery address)-D (technical response)-S (service counter)-M (management level), etc., while NSK China supplier with three Honda has reached All out of a monthly evaluation QCDDMS excellent results, so Guangqi Honda, Dongfeng Honda, Honda (China) jointly awarded the NSK "2010 outstanding supplier Award."

2013年9月26日星期四

NTN bearings distributor in China

NTN backing bearings distributor in China is the world's integrated manufacturer of precision machinery, NTN Bearing is the world's fifth-largest supplier, in 1918, Mr. Niwa (Noboru Niwa), located in Kuwana, Mie Prefecture Kuwana-gun cho rise within the [West Park Rail workers are] began to study and production of ball bearings, NTN Corporation and later by the first letter of his name names. Established until 1960 produced by Toyo Bearing Iwata. Began mass ball bearings. 1989, changed its name to NTN Corporation. 2000, NTN Bearing Group's products all passed the ISO 9000 series certification.

NTN lysn-bearing distributor in China with customer-oriented sales philosophy get more customers. Meanwhile accurate and timely manner to meet the needs of enterprise customers nationwide. NTN bearings distributor in China sales of imported NTN NTN products are trading company in Hong Kong to provide, its quality and quality won the praise of customers in China, the region has a large market share. Provide a variety of products from ball bearings, roller bearings tapered roller bearings to the different categories.

NTN Bearing products include deep groove ball bearings, small and miniature ball bearings, self-aligning ball bearings, angular contact ball bearings, cylindrical roller bearings, tapered roller bearings, self-aligning roller bearings, thrust bearings, special and multi-functional use bearings. NTN bearings are widely used in various automotive, OA office equipment, industrial machinery bearings and some special areas such as environmental and food hygiene.

what is it ? Closer to home

FAG spherical roller bearings are used in new Wimbledon Centre Court retractable roof

Lift the Wimbledon Centre Court , and perhaps someone knows , but you notice the stadium roof , Wimbledon Centre Court retractable roof of a new major feature is translucent, retractable roof , this is how a unique creative roof ah , but this decorative building structure , there is an important role in the structure responsible for its open or close in ten minutes , what is it ? Closer to home, the open and close are inseparable FAG row radial ball roller bearings in this retractable roof is equipped with 300 FAG radial spherical roller bearings and spherical roller thrust tapered bearing FAG bearings to ensure these stadium roof within ten minutes in the open or closed.

Schaeffler for the project provided a total of more than 300 bearings. These bearings consist of fag-aligning roller Slewing bearing , mainly used for supporting both ends of the roof arch hinge radial load and thrust roller bearings for supporting the roof of the cable taut expand the axial loads. Provide maximum self-aligning roller bearings, an outer diameter of 200 mm , can withstand 300kN (30 tonnes) standard radial load , mainly used at both ends of the arch bracket hinge . Thrust roller bearings will assume approximately 600kN (60 tonnes) of the axial loads that are supported by the support structure and roofing materials arched cables produced .

Since the bearing is completely sealed in the hinge group, not exposed to external weather conditions . In other words, Schaeffler can choose from standard products, bearings, its easy to use and offers . These bearings are filled with high-quality internal grease when the roof is expanded , and in the center of the stadium at the top is closed, the top of the dome architecture designed to help building forces from wind, rain , snow pressure.

2013年9月24日星期二

direct the country in various industrial cities and regions

Beijing FAG backing bearings: Goldwind to Schaeffler awarded "Excellent Supplier Award"

FAG bearings sales center Beijing, January 7, 2012, the internationally renowned wind power equipment manufacturer Goldwind in Beijing at the third supplier conference, Goldwind to the worldwide production of rolling bearings and linear motion products leader - Schaeffler Group (FAG, INA, LUK) award 2011 "Excellent Supplier Award", the Schaeffler Group (FAG, INA, LUK) is the only "Excellent Supplier Award" bearing manufacturing enterprises.

Beijing FAG Roller bearing sales center live coverage, the Schaeffler Group (FAG, INA, LUK) Division in the wind energy industry has more than 30 years of experience, research and development and production of wind turbines for the full range of bearing products. Schaeffler Group's INA and FAG brands of about 60 industrial sectors provide more than 40,000 kinds of standard products ranging widely. Schaeffler Group (FAG, INA, LUK) cooperation with Goldwind has been limited to the bearing, the two sides have been in condition monitoring, simulation operations, after-market development and services, product development and application of linear and other fields to work closely .

Schaeffler first wind power bearing areas in China to establish a professional product sales and technical service team, with almost all the major domestic manufacturers of wind turbine manufacturers and supporting the establishment of a strong partnership. Goldwind to Schaeffler awarded 2011 annual "Supplier Excellence Award", FAG bearings distributor in China side believes that this award is the Schaeffler Group leader in the field of wind power in China bearing supplier status once again recognized and affirmed.

Beijing FAG bearings sales center, FAG Bearing stock, direct the country in various industrial cities and regions, welcome your inquiries.

CoCaB Bearings - solution casting plant

Recently, the Schaeffler (FAG) Group in its global video conference FAG showcasing its new product line-CoCaB bearings. CoCaB bearings designed for continuous casting plant solutions developed. Here is learned Chinese distributor FAG content.

Caster Roller bearing (CoCaB) - After the market by FAG Industrial Heavy steel industry specialists and application engineers developed a class of special products for the steel industry. The range includes FAG cylindrical roller bearings, seals or without seals FAG spherical roller bearings, needle roller caster upper bearings and ladle turret of ELGES spherical plain bearings. With special bearing cooling water so that the entire product range more complete.

Specially developed for this application FAG cylindrical roller bearings are the core products of the series. It has a full complement cylindrical roller bearings and spherical roller bearings advantages. Traditional floating side bearing solutions commonly used so far is a compromise, rather than with the use of the optimal solution for this. Therefore, with anti-corrosion performance FAG cylindrical roller bearings are casting floating bearing side specially developed.

CoCaB cylindrical tube bearings advantages are: high radial load; misalignment adjustment of up to 8 points; axial displacement without friction; easy installation and removal quick.

FAG spherical roller bearing shells for the strand guide roller locating bearing side, because here there are high radial and axial loads, and there will tilt produce. Spherical roller bearings in steel mills in extremely harsh environments and high load conditions and reliable operation, they can compensate for shaft deflection and FAG bearing misalignment. Outer diameter of 320 mm, 240 and 241 series has a new sheet steel cage. The high temperature of the double half cage is particularly suitable for continuous casting plant in harsh operating environments.

FAG Bearings train control system application

FAG engineers are good at innovation beyond the traditional practice . This means that challenged the traditional theory , following extraordinary way and dare to look at things with a different kind of perspective . All of these are emerging understanding of the concept of the premise. Recently , FAG Cylindrical roller bearing distributor in China from Germany FAG Group understands , FAG latest train control system developed for FAG Generator Sensor Slewing bearing .

FAG bearings based train control system box and generator sensor bearing (GSB) ( as an independent power source ) combined well , for example, truck , FAG 's electronics engineers , are integrated into the software to learn GSB , so formation of a vehicle unit . Coupled with the information processing system , route operators and railway companies can achieve enhanced security and ease of maneuverability truck . GSB in the number of different signals are recorded and transmitted to the central processor . Complete data ( based on train system ) contains train schedules , route , schedule and risk analysis , location, residence time , and the associated temporary variable part .

And general comparison , FAG GSB in axle by rotational movement of electrical induction magnet . This force is the typical power , 100w 24v .. so just have a separate , self-contained power source, the power storage unit , an increase of more features, such as automatic door, detection switches and sensors. To train control system , FAG Group with a sophisticated electronic system into a so-called commercial -vehicle unit and connecting with senior management information systems. Such signal processing , not only records the FAG bearings , but is also transmitted GPS satellite technology.

at sea installation, simply upgrade once completed lifting .

According MULTIBRID company's design philosophy, the main backing bearings mounted directly on the main frame , the hub and main bearings installed together. Is a compact drive gear box assembly unit generator . In order to ensure reliability and long life requirements , FAG design engineers chose a very low generator speed , load on the lookout for gearbox and generator to minimize the adverse effects , custom double row tapered roller bearings can be load passed to the main frame , so that the gearbox generator unit from impact loads . This design can greatly reduce the weight of the device . By eliminating the high -level gear, fan tower head is relatively light weight of about 300t. So the cabin can be pre- assembled on land , at sea installation, simply upgrade once completed lifting .

To simplify MULTIBRID company fans spindle tapered bearing equipment maintenance work , can be a subsidiary FAG FAG Industrial Services (F'IS) status monitoring equipment. By arranging a large number of sensors , the device can be vibration, temperature changes , and bearing position for continuous monitoring . Any deviation from the positive indicators of monitoring data by experienced experts to assess and take remedial measures to avoid unplanned downtime.

FAG bearings distributor in China , and we briefly shut MULTIBRID Company : Multibrid is a port city located in Bremen, Germany, specializing in marine wind turbine research company whose purpose is to set up its parent Prokon Nord ( Northern Germany over large regional power company ) to provide reliable and technologically advanced marine wind turbines. M5000 is to adapt to the requirements of marine wind farms and the birth of the first level of the ocean 5 MW wind turbines .

Roof design itself as " collapsible hexagonal design ", when not using the roof

Attachment: Wimbledon Centre Court introduced a new retractable roof

Roof both open or closed can provide robust and secure ( does not slip ) of the venue. In the closed position , the natural light through the translucent roof exposure to the grass in any adverse weather conditions can play a protective role on the grass . Roof design itself as " collapsible hexagonal design ", when not using the roof , the roof can be folded into a high compression zone. Even the roof closed, the roof can also create a transparent "open" feeling. The backing bearings roof area of 5200 square meters, developed by a special waterproof material , very strong and full of flexibility. The key elements of the roof design when the roof is in the closed state, a lot of natural light can be irradiated to the grass. Airflow system from the closed space of the condensation detached , so as spectators and players and provide a most comfortable environment inside .

Retractable roof comprises a total of nine tapered bearing plate is divided into two parts: one is 4 , and the other part of the 5 . On either side of each plate are fixed with angled steel . There are 10 frames across 77 meters of the stadium . Each steel wheels supported by a set of ports can be installed in the center court along both sides of the track move . Ready to close the retractable roof , the northernmost part of the stadium to keep the folded state , parked in another part of the southern end . To ensure the accuracy of the roof moves , you need to install a high-precision electronic actuators, servo motor and rocker synthesis system . This system will separate the steel , while steel between the upper and the steel parts of substantially begin until the two parts of the top center of the pitch joints combined stacked flat . Steel is installed on the bottom of the hinge a number of similar components. Schaeffler FAG spherical roller bearings assembled in these hinge . These bearings due to friction is small, and can be carried out right kind of compensation is selected. These bearings are grease lubricated through high-performance , during use, requires minimal maintenance

2013年9月17日星期二

FAG bearings used in household appliances types

Dalian FAG lysn-bearing : FAG Bearings household applications

Dalian FAG bearings sales center and tell you about energy-saving household appliances applications FAG Bearings , FAG Bearing Group launched a household refrigerator compressor used rolling bearings FAG bearings, FAG bearings to enhance the capacity to make a significant contribution to energy efficiency .

Dalian City , has been formed to petrochemicals , electronics, machinery , textile garments, metallurgy , building materials, food, medicine and other industries based industrial system , there are many industrial enterprises are the backbone of Chinese enterprises in the same industry , in order for these companies demand FAG Bearings , FAG FAG bearings sales center in Dalian, China , some of FAG bearing stock , please call 022 -23151509

Dalian FAG Bearings FAG Bearings sales center explain the type used in household appliances and benefits :

FAG bearings used in household appliances types: four different types of FAG thrust ball bearings can be freely combined . There are no band raceways and raceway two kinds of rings , the cage can be made of plastic or stamped steel. All materials are in line with environmental requirements. They are well matched with the frozen liquid , and resistant to different temperatures. In the basic design, the thrust bearing ring metal forming, quenching and polishing, can be used to make bilateral raceway . Depending on the installation location can customize special size bearings .

FAG Slewing bearing used in household appliances benefits : narrow rigid sheet steel cage is a special highlight. Even more than in the past to use the cage of the bearing position is more suitable for conventional plastic cage , since there are higher temperatures. Furthermore , without the need for cryogenic liquid matching test . Thrust ring raceways of the ball to provide a more secure guidance and better load distribution , thereby reducing wear and prolong the service life . There sided with raceway design, can improve the safety performance of household appliances installed .

FAG thrust ball bearings particularly suitable for household refrigerator compressor eccentric shaft bearings. It replaces the usual refrigerator compressor used in household appliances in the installation position of the sliding bearing , and reduce energy consumption of 5% of the entire compressor . Use of such energy-efficient bearing , household refrigerator compressor rated at a level of efficiency can be improved .

KOYO bearings distributor in China

KOYO tapered bearing distributor in China Koyo (Japan's Koyo Seiko Co., Ltd.) is a company with a long history and culture in Japan, ranking third in the world comprehensive bearing manufacturer, Japan KOYO Koyo Seiko Co., Ltd. for the production of one of Japan's four main Slewing bearing , KOYO worldwide users enjoy high popularity and praise the quality of friendship.

Koyo Koyo Bearing was founded in 1921 and has 6,557 employees. In Japan, eight main production plant (all passed ISO9001 certification) and 28 sales outlets abroad have nine production plants, 24 sales points. Koyo Bearing 1999 Bearing Sales by Product Category realized 186.7 billion yen, car steering 119.3 billion yen, 55.1 billion yen other products, 52% of total sales, respectively, 33% and 15%. Koyo bearings are widely used in smelters, mines, steel mills rolled mechanical equipment, power plants, gas turbines, electrical power equipment factory demanding bearings.

KOYO KOYO bearings distributor in China leading products are: KOYO bearings, KOYO deep groove ball bearings, KOYO high-precision bearings, KOYO self-aligning bearings, KOYO Bearings, KOYO flat ball bearings, KOYO short cylindrical roller bearings, KOYO linear guide bearings , KOYO ball screw bearings, KOYO miniature linear guide bearings, KOYO cross roller guide bearings, KOYO reciprocating rotary bushing bearings, KOYO ball slide bearings, KOYO cam follower bearings

Fourth, the cover exposed bearing

Third, replace the lubricant

Oil lubricated Tapered roller bearings in addition to the old oil spilled after, if possible, and then poured fresh oil and let the machine at low speed rotation a few minutes. Residual oil to collect as much as possible contaminants, and then spilled addition to these oil, oil in the best first filtered before use.

Fourth, the cover exposed bearing

1, check the bearings, do not let the Slewing bearing exposed to contaminants or moisture. If the work is interrupted, should be oiled paper or similar material plastic film covering the machine.

2, if the check is performed without removing the case may be cleaned under no masking the bearing to be applied with a brush to coat with oil solvent (whitespirit) cleaning, then a dry lint-free cloth or blow with compressed air dry (be careful not to let the bearing assembly starting rotation).

3, similar to a small mirror and dental probe used to check that the bearing surface of the track, the holder and beads.

Fifth, the implementation of re-lubrication.

A non-encrypted cleaning dust cover or bearing; just wipe the external surfaces can be.

2, if the bearing was damaged when the case is to be replaced. In the periodic maintenance shutdown period than replacement bearings bearing damage caused by the sudden shutdown of the loss of more economic and more.

the lubricant inside the bearing can take away most of frictional heat

Describes the importance of imports bearing lubrication and effect

Lubrication of the bearings, in particular, the fatigue life of the rolling bearing and friction, wear, temperature, vibration, etc. have a major impact. Without proper lubrication, the bearings will not work. Analysis to understand: tapered bearing causes of damage showed that about 40% of the bearing damage are related with poor lubrication. Therefore, well lubricated bearings is to reduce bearing friction and wear of effective measures.

Slewing bearing lubrication effects can be briefly described as follows:

1 using oil lubrication, especially the use of circulating oil lubrication, oil mist lubrication and injection lubrication, the lubricant inside the bearing can take away most of frictional heat, serve as an effective heat sink.

2 in the rolling surface contact with each other or the two form a film between the sliding surfaces of the second surface spaced from the contact surface to reduce friction and wear.

3 has to prevent metal corrosion lubricant effect.

4 lubricated with grease, you can prevent external dust and other foreign matter from entering the bearing, and sealing effect.

5 to extend the fatigue life of bearings.

scraping, should be under the circumstances

class = MsoNormal> 1, scraping, you should carefully check whether the journal is smooth, whether there is rust, bumps and other defects, if any, should first try to eliminate;

2, and then check the contact tapered bearing the journal and the shaft, inspection methods, coated with a thin layer of the shaft shown agents (such as red lead powder, red Qian oil), followed by the journal mounted in the bearing, with positive and negative direction of rotation twenty-three hand to turn the shaft out, check the Roller bearing on the distribution of colored points, if the distribution is not normal or colored dot simply not turn to start scraping.

3, scraping, should be under the circumstances, to take the first re-light, scraping heavy to stay light, scratch big to stay small principle. The first few times, the hand can be heavier, more scrape some metal to quickly achieve better {TodayHot} contacts.

4, when the contact area reaches 50%, it should scuffing. Every once scraped off, wipe the tile surface, and then displayed on the journal repellent check inspection, according to the conditions of exposure scraping until it meets the technical requirements so far.

5, scraping examination can show agents, but the contact point demanding precision Backing bearings scraping the last stage can not use the display agent. Because, painted display agent, coloring bearing point is too large and difficult to determine the actual exposure situation. At this point, you can wipe the journal, bearing directly on the check, and then remove the shaft, the bearing can be seen on the highlights, is the point of contact. And then the highlights for scraping until meet the technical requirement.

Scraping, not only to make the contact points meet the technical requirements, but also to make the contact angle of the side clearance and technical requirements. Usually the first point of contact research, but also to take care of the contact angle, the last Zaigua backlash. However, the contact portion and the non-contact portion not have clear boundaries, wipe the bearing surface with fingers, no trace should be aware

anti-foreign bearing steel DCJ2

How to use the special circumstances lysn-bearing steel

To meet this demand, we must make the material, heat treatment process, shape and size optimization, and user needs and the use of the material together to seek the integration of the surrounding parts. Loaded cars, industrial machinery, household appliances, machinery and other mechanical devices intelligence bearing not only requires a lightweight, compact, and improve bearing performance to meet the requirements too harsh environments use:

1, anti-foreign bearing steel DCJ2

For automotive transmissions and differential bearing device, due to the oil mixed with foreign matter (silt, cutting powder), once this foreign objects into the Slewing bearing rolling surfaces will produce rolling surface indentation caused by the early spalling resistance to foreign developed for this purpose bearing steel.

By inclusion of foreign environment reproducing rolling fatigue test, research to improve the result of the inclusion of foreign environment bearing life, by improving the amount of retained austenite of the surface, to improve the surface hardness and toughness of the matrix have effect.

2, high temperature bearing steel STJ2

With the car engine output power and continuous improvement in industrial machinery and closure of high-speed, bearing using the ambient temperature rises. Desired to develop a temperature at 473 ~ 523K maintain performance of the bearing. In this temperature range, if the implementation of the quenched SUJ2, the hardness is reduced, rolling fatigue life characteristics deteriorate holes.

2013年9月16日星期一

Thrust bearing is installed correctly

How to install the rear thrust bearing test

Install thrust lysn-bearing shaft ring and shaft should examine the vertical centerline. Method is fixed to the tank shell dial gauge face, the head of the table to touch the top of the bearing shaft rotating bearing ring raceway, while observing dial gauge pointer, if the pointer deflection, indicating ring and shaft centerline axis is not perpendicular. Tank shell hole deeper, we can still use an extension of the dial gauge head test.

Thrust Slewing bearing is installed correctly, the seat can automatically adapt to the rolling elements rolling, make sure to scroll down raceway body is located. If installed backwards, not only bearing is not working properly, and each mating surface would be subjected to severe wear. As shaft ring and seat ring and the difference is not very obvious, the assembly should be careful not to mistake. In addition, the thrust bearing race with the bearing hole should be left between 0.2-0.5mm gap to compensate for parts processing, the error caused by mounting inaccuracy, when in operation bearing ring center offset, this gap would ensure its automatic adjustment, avoid touching the friction to operate normally. Otherwise, it will cause severe damage to the bearing.

some really difficult to buy into the bearing varieties

Rolling repair conditions and methods

Rolling is the mass production of mechanical parts, and manufacturing precision requirements are very strict, technically high degree of specialization, so for the most readily available bearing varieties, it should be more economical to purchase than repaired, and only in the following cases before considering the Backing bearings fix the problem, namely:

(1) a large number of large factories are using the same type of bearing failure mainly in the form of its rolling surface wear, fatigue or fretting abrasion, especially damaged parts mostly cage or rolling, while still ring or gasket repair value;

(2) large and extra large bearing on the brink of failure or having lapsed and no significant damage parts, or precious bearings must seek to extend its useful life is;

(3) some really difficult to buy into the bearing varieties, after the failure had no spare parts and repair, especially imported bearings;

(4) tapered bearing a slight injury, such as inventory produced during the mild water, rust, and transport process produces a slight micro abrasion, such cases repaired easily and gesture.

In addition to economy outside bearing repairs as well as its technical, requiring repairer fully understand bearing the corresponding technical requirements, with the bearing and parts in the structure, process and on the characteristics of the material, it would be difficult to ensure the bearing repairs have desirable results.

One, bearing repair cost

the radial basic dynamic load rating

Means a set of rolling Slewing bearing can withstand the constant imaginary radial loads, loads in the basic rating life of one million rpm. The single row angular contact bearings, this load causes the bearing rings to each other is purely radial displacement is generated between the radial component of the load.

8, the axial basic dynamic load rating

Refers to the hypothetical role of the center in a constant bearing axial load lysn-bearing loads in the basic rating life of one million rpm.

9, radial (or axial) equivalent dynamic load

Refers to a constant radial load (or central axial load), the load, the rolling bearing having the same load of the actual life.

10, radial (or axial) Basic static load rating

Means with a rolling body raceways, and the total amount of permanent deformation corresponding radial static load (or the central axis of the static load). If at zero load, roller and raceway (roller bearing) is assumed to be normal or bus (line contacts) when the maximum contact stress, the rolling element and raceway contact produces a total permanent deformation of the rolling element diameter of 1/10000. For single row angular contact bearings, radial load rating of the bearing rings relative to each other due to pure radial displacement of the radial component of the load.

11, radial (or axial) Static equivalent load

The radial static load (or central axial static load) causes the maximum stress by rolling element and raceway contact at the total amount of permanent deformation resulting from the actual load conditions the same as the total amount of permanent deformation.

It can withstand heavy load

SKF spherical roller thrust Backing bearings concept

In spherical roller thrust bearings, the load bearing axis is angled away from the raceway to another raceway. Therefore, bearing in addition to radial loads, but also can withstand axial load simultaneously. Spherical roller thrust bearings Another major feature is its self-aligning capability, which allows a certain degree of axial downtown area between the shaft and the bearing alignment errors.

SKF spherical roller thrust tapered bearing have a lot of asymmetric stick with the specially designed raceway has an excellent fit. It can withstand heavy load, and allows a relatively high speed.

SKF spherical roller thrust bearings depending on the size and series, there are two kinds of designs. Size 68 or less suffix E bearings, window design with just the press cage with rollers and shaft ring composed of an inseparable component. All other bearings are fitted with machined brass or steel cage, the cage consists of a ring mounted on the shaft of the guide sleeve. Shaft ring, rollers and cage form an inseparable component.

high load capacity

Single-row angular ball bearings suffix knowledge

B 40oC contact angle

E high load capacity

A Backing bearings the rounded edges are the same

Y copper punched retainer , design changes , such as with additional numbers to distinguish : Y1

M Machined brass cage . Cage design or material change with additional numbers to distinguish such as : M2

J no liquid hard copper punched retainer . Cage design or material change with additional numbers to distinguish , such as : J1

F made ??of copper or ductile iron machine cut cage. Cage design or material change with additional numbers to distinguish , such as : F1

P glass fiber reinforced plastic mold injection cage.

P5 dimensions and rotational accuracy considerably ISO tolerance 5 ( more than P6 precision )

P6 Schaeffler Group's three active Division

With FAG, LUK and three strong brands INA Schaeffler (Germany FAG bearings) Group, its mainly active in the automotive division, industrial and aerospace division Division.

Germany FAG Slewing bearing Group Automotive Division: skilled, powerful Schaeffler Group's largest customer is the most important automotive industry, about 60% of the Schaeffler Group's sales from the automotive industry, the Schaeffler Group, as an almost all major automobile manufacturers and suppliers a reliable partner, FAG bearings Group Automotive Division for the entire drive train, passenger commercial vehicle engines, chassis, transmissions and other parts units and suppliers to provide the most professional knowledge and innovative ideas and products.

Improve the practical method of fitting accuracy

In order to improve the Backing bearings with precision the actual installation, you must not make use of the bearing deformation measurement methods and measuring tools, Slewing bearing and cylindrical bore size of the mating surfaces of the actual precision measurement can be measured on the inner and outer diameters All items to be measured, and the measured data to make a comprehensive analysis of this as far and precision worthy of shaft and housing bore bearing mounting portion size. In actual measurements made ??with the respective shaft and housing bore size and geometry should be the same with the measuring bearing temperature conditions.

To ensure the effect of a higher actual mating shaft and the lysn-bearing bore to match the surface, the roughness should be as small as possible.

In making these measurements, should be cylindrical and the bearing bore, the housing bore and the shaft, and a corresponding surface of the chamfered sides near the assembly, respectively, showing the maximum deviation to make the direction of two marks, so that in actual assembly, the mating alignment of both the maximum deviation of the same position, so that after assembly, the two sides can be partially offset by the deviation.

Directional signs made ??two aims can compensate for deviations into account, even if both sides supporting each rotation accuracy improved, but also between the two bearing seat hole and both ends of the journal concentricity error partially eliminated. Surface hardening on the mating surfaces to implement measures, such as sandblasting, with a diameter slightly larger than the precision plunger plug holes, once inside, there is help to improve the fitting accuracy.

2013年9月15日星期日

KOYO company expanded U.S. plants

November 19, 2010, KOYO Slewing bearing distributor in China learned from Japan KOYO headquarters, KOYO company plans to invest $ 30 million expansion of its in Tennessee, Washington County, factories, the new plant is expected to add 61,000 square feet, employees increased to 125 people.

KOYO company expanded U.S. plant background: KOYO U.S. company is a wholly owned subsidiary of JTEKT Corporation, JTEKT company produces steering systems, power transmission, backing bearings and machine tools is a world leader. JTEKT is the world's largest auto parts suppliers, the company's U.S. subsidiary Koyo Toyota, Honda, Ford, GM, DaimlerChrysler and BMW and other brands of one and two suppliers. U.S. companies in the automotive market share KOYO gradual growth of our well proven product quality, so taking a step forward expansion of U.S. factories to meet the growing market demand.

In this KOYO company plans to expand their U.S. plants, Koyo Vice President Steve McCullough said: "For everyone, 2009 is a very tough year, Koyo company is in such an environment, reposition full use of its advantages in the automotive industry, making the performance of the company to be picked up. extension Washington County facility for our entire company's long-term development strategy and growth for the company, it is a very important part. KOYO in the U.S. auto market share gradually our growth is the result of joint efforts of all staff, but also for product quality KOYO good proof. "

KOYO Koyo Seiko Co., Japan club produced tens of thousands of high-precision, high-quality products KOYO bearings to provide information on aerospace technology, computer components, motors, high-speed trains, rapid transit trains, industrial machinery, CNC lathes, high-precision machining , car and motorcycle industry, steel industry ... and other important component of choice for the best

SKF has developed the products

SKF solutions for racing system , which is the unit of SKF's racing in karts Chiesa Corse racing team provides customized technology solutions, primarily for racing wheel tapered bearing applications and engines were designed . The device uses the car dust cover unit that allows its bearings under race conditions convenient for cleaning lubrication, thus ensuring the efficiency of racing high-speed rotation , as well as long-term reliable service life.

At the same time , SKF car unit of the car rear axle designed for reliable quality shaft mounting and rotating concentric with the real and the low friction ball locking device , thereby providing the best speed, rigidity and response . In addition, a high-performance engine Roller bearing are also racing to give a more ample power , rigidity and reliability. Also located in this race means outer surface and patented groove profile SKF Group is designed to avoid this during the game supporting devices due to the risk of dislocation caused .

The application of advanced products and technologies to provide customers with enhanced SKF fine professional solutions. SKF -based services industry over a hundred years of accumulated knowledge and experience , SKF has developed the products, technologies and services in various capacities ; more important is that , depending on your business realities and specific needs , SKF solutions factories have to do is apply this knowledge and ability and integrate our modular service designed to meet your requirements for the maintenance service solutions.

SKF solutions for racing system

We know , organized by the FIA Spanish Aragonese Zuera 2010 World Cup tournament champion team is Chiesa Corse racing team , there is SKF's irreplaceable credit, why do I say ? Here SKF distributor in China to answer your questions .

Chiesa Corse racing team designed and manufactured by the company SKF Cardin axle unit and cylindrical roller bearings engine solutions for Chiesa Corse racing team provides the best speed , rigidity and emergency response , and to ensure that the car high-speed rotation efficiency and long reliable service life , thus engine SKF bearings for high performance racing gives more adequate power , rigidity and reliability. Here are SKF bearings distributor in China 's detailed report.

SKF solutions for racing system , which is the unit of SKF's racing in karts Chiesa Corse racing team provides customized technology solutions, primarily for racing wheel lysn-bearing applications and engines were designed . The device uses the car dust cover unit that allows its bearings under race conditions convenient for cleaning lubrication, thus ensuring the efficiency of racing high-speed rotation , as well as long-term reliable service life.

At the same time , SKF car unit of the car rear axle designed for reliable quality shaft mounting and rotating concentric with the real and the low friction ball locking device , thereby providing the best speed, rigidity and response . In addition, a high-performance engine backing bearings are also racing to give a more ample power , rigidity and reliability. Also located in this race means outer surface and patented groove profile SKF Group is designed to avoid this during the game supporting devices due to the risk of dislocation caused .

The application of advanced products and technologies to provide customers with enhanced SKF fine professional solutions. SKF -based services industry over a hundred years of accumulated knowledge and experience , SKF has developed the products, technologies and services in various capacities ; more important is that , depending on your business realities and specific needs , SKF solutions factories have to do is apply this knowledge and ability and integrate our modular service designed to meet your requirements for the maintenance service solutions.

Nanjing NTN bearings, NTN invest three hundred million yen plant in India

2010.11.05, sales center in Nanjing NTN Bearing NTN distributor in China until we learn from the Japanese NTN Corporation plans to invest three hundred million yen building a second home in India, bearing factory, mainly produces constant velocity joints and axle tapered bearing to meet local and Asia automobile manufacturers demand.

Japan NTN construction in India's second bearing in the southern city of Chennai, India, on the outskirts of the construction of the new plant is expected to start from the beginning of March next year, the initial investment of about 300 million yen (equivalent to $ 3,700,000). Meanwhile, the plant is expected to start from April 2012 mass production of constant velocity joints and axle Stainless steel slewing bearing After the completion of the new plant is expected to NTN's sales in India will be 5 times the original, that is, from 2009 ¥ 4 billion for fiscal year 2015 financial year rose to 200 billion yen.

Currently, NTN's existing plant in India is located in a northern Haryana. In India NTN Bearing Factory and then building a second home for your local Toyota, Renault and other car manufacturers supply auto parts.

According to NTN China introduced, NTN in February next year and a Chinese bearing manufacturer to establish a joint venture company. The new company investment will reach $ 93.5 million, equivalent to 7.7 billion yen. The new company will be built in Luoyang, Henan Province, NTN Bearing Corporation Luoyang LYC Bearing Company and each holds 50% ownership. NTN will adopt the joint venture to produce automotive wheel bearings. Is expected to start production in October 2012. The new plant will produce for the automotive industry, wheel bearings and needle roller bearings, fiscal year 2015 sales are expected to reach 70 to 8,000,000,000 yen.

bearing as many of the core components of mining machinery

Seiko Corporation of Japan (NSK LTD.) On October 26 -29 days participating in the Beijing National Agricultural Exhibition at the 2010 China International Coal Fair, here is the distributor of NSK China's reported.

2010 China International Exhibition, organized by the State Coal Mine Safety Supervision backing bearings the National Energy Administration, China Coal Industry Association co-sponsored by the State Administration of Production Safety Supervision and Management Center for International Cooperation contractor, the theme was "safe and efficient mining, green carbon use." In addition to showcasing the exhibition changing the mode of development of coal industry's achievements in scientific and technological innovations of coal enterprises, the main show coal production, preparation and processing, mine construction, coal transportation, coal mine safety, geological exploration, coal chemical industry, mine explosion practical aspects of advanced technology and equipment.

Exhibition 2010 Beijing China International Exhibition Coal origin of the Chinese, the United States, Britain, Japan, Australia and other countries and regions, more than 10 research institutions and numerous famous. As the world's largest Stainless steel slewing bearing manufacturer Seiko Co., Ltd., one of Japan (NSK), also participated in the exhibition.

And exhibited a series of devices, bearing as many of the core components of mining machinery, almost throughout all the equipment in the field. 2010 Beijing China International Exhibition on Coal, NSK exhibited a series of mine and all kinds of Bearings NSK Bearings special installation tools, test equipment, in-kind exhibition and novel video presentation attracted up to 2,000 people, the number of daily visitors to visit, a total of issue various samples sent up to 1,555 books, by the visitors alike.

By NSK exhibitors 2010 Beijing China International Exhibition Coal, NSK with more exhibitors had extensive experience and information exchange, consolidate and develop more win-win partnership. The exhibition on the further development of NSK, has played a catalytic role.

NSK exhibitors 2010 Beijing China International Exhibition Coal

Seiko Corporation of Japan (NSK LTD.) On October 26 -29 days participating in the Beijing National Agricultural Exhibition at the 2010 China International Coal Fair, here is the distributor of NSK China's reported.

2010 China International Exhibition, organized by the State Coal Mine Safety Supervision tapered bearing the National Energy Administration, China Coal Industry Association co-sponsored by the State Administration of Production Safety Supervision and Management Center for International Cooperation contractor, the theme was "safe and efficient mining, green carbon use." In addition to showcasing the exhibition changing the mode of development of coal industry's achievements in scientific and technological innovations of coal enterprises, the main show coal production, preparation and processing, mine construction, coal transportation, coal mine safety, geological exploration, coal chemical industry, mine explosion practical aspects of advanced technology and equipment.

Exhibition 2010 Beijing China International Exhibition Coal origin of the Chinese, the United States, backing bearings Japan, Australia and other countries and regions, more than 10 research institutions and numerous famous. As the world's largest bearing manufacturer Seiko Co., Ltd., one of Japan (NSK), also participated in the exhibition.

And exhibited a series of devices, bearing as many of the core components of mining machinery, almost throughout all the equipment in the field. 2010 Beijing China International Exhibition on Coal, NSK exhibited a series of mine and all kinds of Bearings NSK Bearings special installation tools, test equipment, in-kind exhibition and novel video presentation attracted up to 2,000 people, the number of daily visitors to visit, a total of issue various samples sent up to 1,555 books, by the visitors alike.

By NSK exhibitors 2010 Beijing China International Exhibition Coal, NSK with more exhibitors had extensive experience and information exchange, consolidate and develop more win-win partnership. The exhibition on the further development of NSK, has played a catalytic role.

2013年9月13日星期五

one of Japan (NSK), also participated in the exhibition.

NSK exhibitors 2010 Beijing China International Exhibition Coal

Seiko Corporation of Japan (NSK LTD.) On October 26 -29 days participating in the Beijing National Agricultural Exhibition at the 2010 China International Coal Fair, here is the distributor of NSK China's reported.

2010 China International Exhibition, organized by the State Coal Mine Safety Supervision backing bearings the National Energy Administration, China Coal Industry Association co-sponsored by the State Administration of Production Safety Supervision and Management Center for International Cooperation contractor, the theme was "safe and efficient mining, green carbon use." In addition to showcasing the exhibition changing the mode of development of coal industry's achievements in scientific and technological innovations of coal enterprises, the main show coal production,Roller bearing and processing, mine construction, coal transportation, coal mine safety, geological exploration, coal chemical industry, mine explosion practical aspects of advanced technology and equipment.

Exhibition 2010 Beijing China International Exhibition Coal origin of the Chinese, the United States, Britain, Japan, Australia and other countries and regions, more than 10 research institutions and numerous famous. As the world's largest bearing manufacturer Seiko Co., Ltd., one of Japan (NSK), also participated in the exhibition.

Such as Midea, Gree and other enterprises

Seiko Corporation president Norio Otsuka backing bearings that China's development is definitely the future of the center is located in central Hefei , rather than along the coast. Therefore , NSK is the core of the product line , the global share of the first ball bearing project investment in Hefei . Hefei NSK NSK bearing production company is the first in China to set up 12 plants will be equipped with the most sophisticated equipment , NSK outside of Japan to lysn-bearing the largest production base. NSK Hefei plant will be subject to local employees to operate in China , while the rapid development of industry from around the world to provide NSK's high quality products. Inland areas will be the core of the future development of China , Hefei, Anhui able to have the opportunity to build factories and regions, contribute to the community , it is our pleasure to thank the local government to give NSK this opportunity.

Previously , NSK and Hefei appliance industry companies have a lot of good business dealings . Such as Midea, Gree and other enterprises, have used NSK's products. As China 's Hefei appliance 's status , NSK is also an important consideration in choice of investment land basis . In China , NSK is accounted for the highest share of bearing manufacturers in the future but will utilize the brand strength in the rapidly changing Chinese market to grow faster .

Beijing Auto Show as China's largest auto show

Beijing NSK backing bearings sales center is said, May 2, 2010, the 11th Beijing International Automotive Exhibition has been the industry as "by far the world's largest auto show next successfully concluded in the 10-day show in , to "Imagine a Green Future" as the theme, demonstrating people, vehicles and nature live in harmony ideal picture for our brand to provide quality green innovation platform for the display as the world's top-class auto parts conglomerate - NSK bearings company, NSK portrait artist of the 11th Beijing International Automotive Exhibition. classic booth design, top-notch products, professional technical explanation, showing NSK for endless pursuit of high quality products and excellent professionalism NSK employees, cited to many domestic and foreign car manufacturer's attention.