Roller Bearing from printers, fax machines to monitor, used in household products in their daily lives have a flange bearing products show space technology. In the standard ABEC-1 level size and accuracy requirements, produced by the bearings, to meet the general purpose products.

Products with a flange on the outer ring, so that the axial positioning easier; single row cylindrical roller bearing is no longer needed, it becomes more economical. In order to obtain a low friction bearing torque, high rigidity, good rotation accuracy, the use of a small ball diameter. Use of the hollow shaft to ensure that the weight and the wiring space.

The biggest feature is the bearing flange and became one. When the end of the shaft is not connected pieces, such as the board needs to be fixed in the plane, while on the wall flange bearing an expression of its advantages.

In the ultra-small aperture miniature bearings, bearing dust cover plate can be divided into ZZ series, RS rubber bearing seals series, Teflon Crossed Tapered Roller Bearing seals series, flange series, stainless steel series, ceramic ball series. Miniature ball bearings with a wide range of uses. For high-speed rotation, low friction torque, low vibration, low noise requirements.

Flange bearings are suitable for all types of industrial equipment, small rotary motors, office equipment, micro-motor soft drive, pressure rotor, dental burs, hard disk motor, stepper motor, drum recorders, toys, models, fans, pulleys, rollers, transmission equipment, entertainment equipment, robotics, medical equipment, office equipment, testing equipment, gear, transmission, motor optics, imaging devices, card readers, electrical, precision machinery, electric tools and toys.

How to prolong the service life of the roller bearing Whether buyers or sellers are concerned about the length of life of the bearing. Such as: flange bearings mainly bear radial load, but also to support radial and axial loads. But for the life of the Roller Bearing are not very understanding, the following three steps will teach you to extend bearing life:

(1) In order to make the radial clearance between the bearing retainer and the bearing ring is provided with greater eccentricity than the internal structure has been improved;

(2) using the FEM analysis, by optimizing the shape and thickness, etc., to improve the strength of the retainer;

(3) In order to prevent a decrease in surface damage caused by the lubricating oil in the bearing ring in the design of the guide groove.

Roller bearing is cylindrical, conical or drum-shaped roller for rolling element bearing. Roller bearings are mainly radial cylindrical roller, double row spherical roller, tapered roller and thrust roller and structure type.

2015年2月28日星期六

2015年2月15日星期日

Calculation of the series bearing of tone

series bearing should ensure the outer spherical raceway and roller and raceway ask radial clearance at the contact line in the direction of the supporting, the radial clearance. Effect of self-aligning roller bearing radial clearance C, the main factors are: outer ring spherical Lang was D.. Inner ring diameter

Distance of two roller and roller contact by diagonal ask. 320 & 329 series bearing The maximum diameter of D and the spherical roller

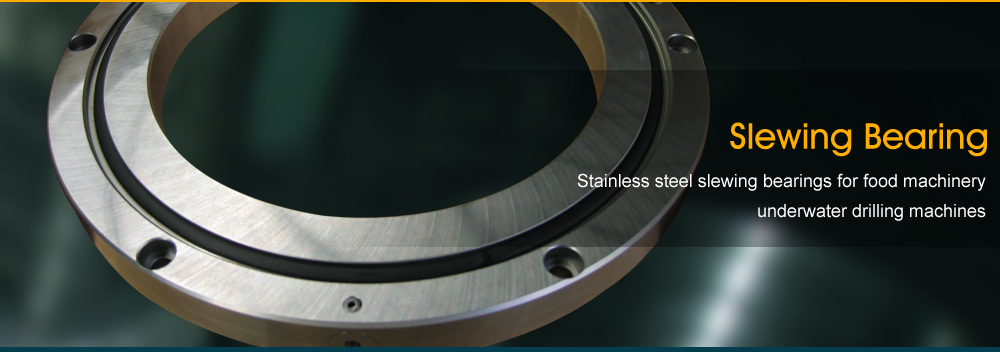

What is different. Spherical roller bearings supporting the identification process, the outer ring spherical raceway diameter deviation and the inner ring two most road diagonal distance deviation measurement and centripetal bearing the general differences. Measurement of packet and Slewing Bearing raceway diameter deviation is generally performed by D924, bore dial indicator instrument; measurement packets in which two rolling deviation road diagonal distance is quite difficult. There are two methods used at present: don't choose an approximate diagonal distance measurement method, another is the method of measuring diameter of roll.

series bearing is complex, precision bearings many factors affect the radial clearance. Only by grouping calculation matching is not guaranteed to pass the radial internal clearance of the bearing. This kind of bearing must be clearance in the matching test for the feast. Matching efficiency can reach the higher matching ginseng powder - revised. Aligning roller on the radial travel clothes measuring bearing commonly used in removing. At present, most manufacturers use 12 measurement device and plug K by way of.

2015年2月11日星期三

The structure and properties of paired tapered bearing

(1) paired tapered bearing the angular contact ball bearing deep groove ball bearing basic similar shape, there is a ring with only a wall, the other side slope. Compared with the same series of deep groove ball bearings with inner diameter specifications, the difference lies in the cage structure and with the number of the steel ball a little more.

(2) paired tapered bearing in the deep groove ball bearing inner ring angular contact ball bearing with outer slope of the inner ring is completely general, such as the inner ring to the deep groove ball bearing 6204 generic row angular contact ball bearing 7204AC.

(3) the angular contact ball bearing retainer is real shape or stamped, no need of rivets.

(4) the limit speed angular contact ball bearing is higher than that of deep groove ball bearing the same size.

(5) Crossed-roller-bearing can bear radial load, also can withstand a one-way axial load is larger, the contact angle is large ratio the bearing axial load and radial load is bigger.

(6) even bear radial load, also produce axial force, so the general angular contact ball bearings are used in pairs.

(7) the angular contact ball bearing Ding is, because of the effects of axial pre load after installation. slim bearings Can eliminate bearing internal clearance, so relatively improve the rotation accuracy of R bearing. The application example in the machine tool spindle high precision, can make the radial and axial spindle runout minimum.

(8) two or more than two angular contact ball bearing group, can bear double direction axial load, or increase the bearing capacity of the single direction axial load.

(9) paired tapered bearing the pre load can obtain more rigid and maintain long-term rotation precision characteristics of bearing the original.

2015年2月7日星期六

Roller Bearing the assembly process

Self-aligning ball bearing assembly process is as follows:

(1) ring demagnetization, cleaning.

(2) double row cylindrical roller bearing the outer raceway size deviation.

(3) divided into the inner stain size deviation.

(4) Roller Bearing the holder is arranged on the inner ridicule and arranged two column ball, symmetric less loaded two balls.

(5) the inner components on the outer ring of sets.

(6) check clearance.

(7) Tapered roller bearings the supplementation of two steel balls.

(8) appearance inspection, finished product inspection rotation flexibility.

(9) Roller Bearing the demagnetization, cleaning, dehydration, drying.

(10) -- oil, packaging.

2015年2月3日星期二

Technical Requirements series bearing

Classification Summary Rolling classification of rolling bearings: Rolling bearing load bearing structure type classification said contact angle is divided into different radial bearings are mainly used to bear radial load Rolling nominal contact angle nominal contact angle divided into radial contact bearings nominal contact angle heart to heart contact bearings bearing nominal contact angle greater than radial bearings thrust bearings are mainly used to bear axial load Rolling nominal 2002: Machine. 1. By 320 & 329 series bearing structural type classification (1) can bear the load bearing their direction or nominal contact angle, divided into: a) radial bearings ----- mainly used to bear radial load bearing, nominal contact angle from 0 to 45. Press nominal contact angle is different, is divided into: radial contact bearings ----- nominal contact angle is zero radial bearings: Radial angular contact bearings ----- nominal contact angle greater than radial bearings 0-45 of . 2) thrust bearing ----- mainly used for axial load bearing, the nominal contact angle greater than 45-90. Press nominal contact angle is divided into different: Axial contact bearings ----- nominal contact angle of 90 thrust bearings: Axial angular contact bearings ----- nominal contact angle greater than 45 but less than 90 of the thrust bearing. (2) the type of rolling element bearing according divided into: 1) rolling the ball as the ball bearing -----: 2) series bearing the roller bearings for the rollers -----. Roller Bearing press roller type, is divided into: NNCF series bearing cylindrical roller bearings ----- rolling body is cylindrical roller bearings, cylindrical roller ratio of length to diameter of less than or equal to 3; needle roller bearings --- - rolling body is needle bearings, needle length to diameter ratio greater than 3, but a diameter less than or equal to 5mm; tapered roller bearings ----- rolling body is tapered roller bearings; spherical Roller bearings eleven rolling body is spherical roller bearings. (3) whether the bearing aligning their work is divided into: 1) aligning bearings ----- raceway is spherical shape, able to adapt to angular deviation and angular movement between the two raceways of the bearing axis ; 2) non-aligning bearing (rigid bearing) ----- able impedance path between roller bearing axis angular offset. (4) according to the number of rows of rolling elements bearings, divided into: 1) single row bearings ----- has a list of rolling element bearings; 2) ----- double row bearings have two rows of rolling element bearings; 3) ----- multi-row bearings with more than two rolling element bearings, such as three, four bearings. (5) whether the separation bearing their part, are divided into: 1) separable bearings ----- bearings with separable components; 2) can not be separated after the final bearing ----- bearing supporting rings are freedom can not be arbitrarily separated bearings. (6) bearing their structure and shape (if no filling slots, without inner and outer rings and structural shapes, ribs, and even whether the cage, etc.) Crossed-roller-bearing can also be divided into a variety of structural types. 2. rolling bearing outside diameter size classification bearing their size, divided into: (1) series bearing ---- nominal diameter size range of 26mm or less bearing; (2) a small nominal outer bearing ----- diameter size range of 28-55mm bearings; (3) small and medium sized bearings ----- nominal diameter size range of 60-115mm bearings; (4) in the large bearing ----- nominal diameter size range of 120-190mm bearing (5) large bearing ----- nominal diameter size range of 200-430mm bearings; (6) large bearings ----- nominal diameter size range of 440mm or more bearings. Rolling numerous types and sizes, in order to facilitate the design and selection, standard specifies the code represented by the rolling bearing type, size, structure, characteristics and tolerance level and so on. (Alternative GB272-88), Rolling Code constitutes as shown in the table. Rolling Code code representation purposes: to characterize the structure of the rolling bearing, size, type, slim bearings precision, code constitutes: Front code - said bearing subassembly basic code - said after bearing types and sizes, such as the main feature set code - indicates the accuracy of the material bearing the characteristics of diameter code: ID Code × 5 = internal diameter special case: d = 10 12 15 17 code is: 00010203 size series Code: used to express the same outside diameter and width of the inner diameter but different bearings, see right. OD Series Code: special light (0,1), light (2), middle (3), weight (4) Width Series Code: normal width to "0", usually not marked. But for tapered roller bearings (3 classes) and spherical roller bearings (class 2) can not omit the "0".

订阅:

博文 (Atom)

.jpg)