Roller bearing is cylindrical, conical or drum-shaped roller for rolling element bearing. Roller bearings are mainly radial cylindrical roller, double row spherical roller, tapered roller and thrust roller and structure type.

2014年7月28日星期一

improvepaired tapered bearing the load capacity and rigidity

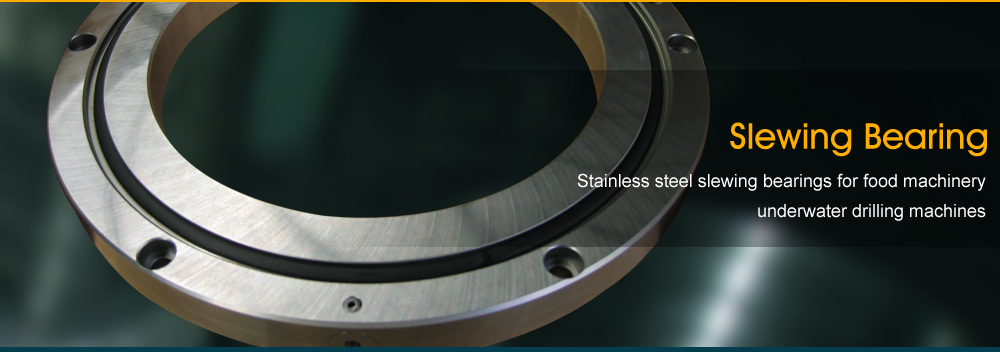

bearings distributor, professional sales agents bearings, bearings provide customers with quality products that help companies reduce costs, improve economic efficiency and other aspects of business has made tremendous contributions. We learned paired tapered bearing from the distributor of Bearing Stainless steel slewing bearing Corporation announced : In order to adapt to the ball screw support machine part , developed to achieve " world's largest " load capacity angular contact ball bearings and machine tools as bearing series of product supply .

distributor, to understand the mechanism and characteristics of

angular contact ball bearings ball through increased size and maximizing the number of balls , improve the load capacity Roller Bearing and rigidity , longer product life , because with both sides sealed , so no installation bearing cleaning , and lubricating plus oil Slewing Bearing addition, the - sealed bearings have a long life oil , no way to add fat . Moreover, the mounting bolt holes located in the outer ring , bearing box is easy to install . Since the sealing lip and the improvement it can only result in increased friction loss torque

2014年7月24日星期四

the vast majority of medium and large companies are now series bearing products do not need a full inspection

Bearing outer ring after quenching, tempering and other heat treatment after , can improve product strength, hardness , wear resistance , fatigue strength and toughness . Previously, the use of process equipment bearing mesh belt furnace and quenching furnace rollers , Slim-bearing tempering, there has been distortion problems affecting the efficiency quality. Especially greater than 150 mm in outer diameter of the large product , the deformation is more pronounced. In recent years, bearing the company's market has been expanding from the traditional automotive industry market more towards wind power bearings, machine tool bearings and other emerging industries range , product specifications growing, medium and large Slewing Bearing outer ring more and more . How to solve the problem of a product deformation caused by the traditional process , the company has become an urgent need to address the "big obstacle ."

Since the deformation meet the requirements, the vast majority of medium and large companies are now bearing products do not need a full inspection , plus reducing stress to both shaping and processes , in the middle class remains unchanged, the product flow rate, greatly improving the production efficiency. Furthermore , the bearing outer taper becomes smaller, the subsequent grinding allowance is reduced accordingly. In terms of cost savings , shaping, five employees to streamline the inspection process , the annual wage bill savings of at least 200,000 yuan ; same time, to reduce stress and subsequent shaping of the original 40,000 yuan per year of electricity use , the benefits of these savings are very impressive .

2014年7月15日星期二

High dust and grease paired tapered bearing sealing performance of both performance

High dust and grease sealing performance of both performance: Ball-ring seal with a special design, the outer sealing lip blocking external foreign invasion, the inner grease seal lip to prevent internal leakage. Compared with the general screw, screw-ring "to reduce the amount of foreign matter 1/30 or less, grease sealing performance and Slewing Bearing increased 3 times, in order to achieve a long tool life, reduce environmental pollution.

Low torque contact seals: Ball-ring seal lip shape using the most optimal design, and the use paired tapered bearing of special resin material, low friction contact with the screw shaft, simultaneously with high sealing performance and low torque performance, to meet the high-speed and high-precision machine tool requirements.

In 2005 developed a high dust seals, laser processing machines are widely used in machine tools, woodworking Backing Bearings machines for use in harsh environments. 2007 based on this technology to develop a grease seal ring and the injection molding machine market has been widely praised. With this sealing technology further developed the machine with the "-ring Ball", high performance dust and grease sealing performance of both low torque and achieve long tool life and reduce environmental pollution. Machine paired tapered bearing tools "-ring Ball" as the latest high-speed ball screw machine tools, will start selling in April 2011, is expected in 2013 with a high-speed ball screw machine total sales will reach 50 billion yen.

订阅:

博文 (Atom)